WEIGHMate – what weighs on your business

WEIGHMATE: THE FRONT- LIFT WEIGHING SYSTEM

“Non – Certified” SystemThe WEIGHMATE FRONT- LIFT WEIGHING SYSTEM (“WEIGHMATE FLS”) has developed over a six-year period, where it has progressed from idea to prototype and subsequently, through a number of preliminary Systems, into the current model – the WEIGHMATE FLS VERSION 3 (“WEIGHMATE FLS V3”). Simply put, the WEIGHMATE FLS V3 System is a dynamic, variable-angle, weighing device that can weigh on the move and on unstable surfaces.

Technically, the System is a dynamic (non-static), variable-angle, weighing device that incorporates load-cells, accelerometers, unique mechanical weight transference design, ‘real-time’ signal filtering and multi-sensor incorporation algorithms to log, store, present and transfer the signal into a final, adjusted, true weight.

The WEIGHMATE FLS V3 allows companies to assess the waste by weight and not just, as per the industry norm, volume. Historically, these trucks have used weighbridges to weigh the total load of the truck, with this procedure being clearly time-consuming (as there are not weighbridges at every collection point) as well as lacking specific accuracy for individual loads.

The design of the WEIGHMATE FLS V3 is very different to the vast majority of our competitors, with the System encapsulating the entire dynamic, weighing system within the lifting forks – thus making it a direct (rather than an indirect) weighing system capable of providing greater accuracy and reliability.

The System has been designed to be totally automated, which greatly reduces operator intervention and/or error, and is modular in design which allows for easy removal, maintenance and serviceability – thus providing minimum down-time for the trucks during servicing or repair.

Additionally, the WEIGHMATE FLS V3 is both capable and adaptable for future upgrades – with the System not requiring a total re-fit for add-on peripherals (such as printers and wireless communications) or upgrades of IT software – and the WEIGHMATE FLS V3 is not limited to any operating system, thus allowing the saving and downloading of the captured information to most databases and IT systems.

In summary the WEIGHMATE FLS V3 is:

- Accurate – current data supports a +/- 5% maximum error.

- Dynamic – the System can weigh on the move.

- Variable angle – the System can weigh on an angle.

- Durable and reliable – the System is robust and can withstand the relevant extremes of the industry working environment, temperature, humidity and handling.

- User-friendly – the System is totally automated and does not require truck drivers (users) to significantly change their current working methods or schedules.

- Modular – the design of the System makes it easy to install, remove and service.

- Upgradeable – the design of the System makes it easy to add peripherals.

- Open – the System provides the ability to save and download the captured information to most databases and IT systems currently used by waste management companies as well as not being limited to any operating system.

“Certified” System

The WEIGHMATE FLS V3 also provides the basis for the unique “certified” weighing system developed by TLIA which has been approved by the National Measurement Institute (NMI) – this system currently titled, the WEIGHMATE FLS V3C.

There are two types of government certification:

- EMC (Electromagnetic Compatibility): This is the only government accreditation that the product needs before it can go to market – EMC certification was completed by December 2003.

- National Measurement Institute: The NMI is the national governing body that regulates the standards that a weighing device must meet if it is to calculate a direct dollar to weight charge, which is then charged to the customer. (Certification granted in August 2004) The WEIGHMATE FLS V3C provides all of the qualities and abilities of the V3 System, but will also meet all of the NMI/Government requirements necessary for a waste company to directly charge a client for the weight displayed by the System for each individual collection – a situation that currently does not exist in Australia. Components The WEIGHMATE FLS VERSION 3 consists of the following four main components:

Weigh Arms: Each system has two Weigh Arms which contain the mechanical ‘weigh-bridge’, motion sensors, electronics and algorithms to calculate the weight applied to each arm, at various angles and various motions. Each Weigh Arm is a separate individual entity that can be interchanged between trucks as needed.

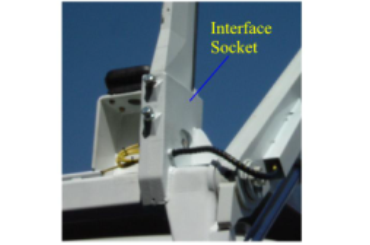

- Socket Interfaces: These are the mounting points that the Weigh Arms are affixed to the truck. The Socket Interfaces allow easy removal of the valuable Weigh Arms or any other fork/arms that are fitted to truck. Our Socket Interfaces will result in arm removal times between 15-30 minutes as opposed to the current 12-24 hours experienced in the industry.

- Frame Processing Unit: Located on the main lifting mechanism of the truck. It processes the signal between the two arms and communicates this to the Cabin Unit. The Processing Unit can also measure motion and it can incorporate this into its calculations where needed.

- Cabin Unit: Located within the driver’s cabin for the operator/driver to see and use with minimal interference with normal driver operations. The Cabin Unit is the final storage and presentation point for the collected information, giving the operator both the weight of each lift and the total cumulative weight of the truck. Additionally, it has the ability to communicate this data real time through a serial port to any information technology system that may be currently in operation.

Downloadable Documents Can Be Found In BLUE Below…

“If you can measure it, you can manage it”

Find out now how we can deliver on this Mate's rates